Pipe Bending

Hızlanlar's

production

department

has

been

divided

into

three

separate

areas

as

CNC

Pipe

Bending,

Pipe

End Forming and Assembly.

In

CNC

pipe

bending

department,

there

are

12

CNC

pipe

bending

machines

capable

of

bending

steel,

copper, stainless, brass and aluminum pipes starting from 4.76 mm diameter up to 80 mm diameter.

And

in

pipe

end

forming

department,

end

forming

round,

ring,

diameter

enlarging

and

reduction

operations

could

be

made

by

13

end

forming

machines,

and

also

starting

from

4.76

mm

diameter

up

to

80

mm

diameter.

In

our

assembly

department,

rubber

and

metal

combining

of

hydraulic

hoses

and

pipes

are

executed

with

13 presses.

Production

is

controlled

in

its

every

phases

with

three

dimensional

measuring

device

and

3

dimensional

fixtures

approved

by

quality

control authorities.

Operators

working

in

production

are

developed

in

technological

and

also

in

social

areas

with

continuous

trainings

for

the

purpose

of

protecting our quality level worth of the name of Hızlanlar and for bringing it to better levels.

Machining

By

the

statistical

works

performed,

banjo

rings,

center

bolts,

hose

ends,

brake

heads,

nuts

and

bushings,

Cpks

of

lathes

are

continuously kept under observation and produced with great care.

In our machining department;

Laser Cutting and Marking

Universal Milling, 1 piece

Universal Lathe, 5 pieces

CNC Lathe, 4 pieces

Automat With 6 Shafts, 1 pieces

Index ABC, 3 pieces

CNC process center, 1 piece

Surface grinding, 1 piece

Hydraulic presses, 6 pieces

Triple perforating, 1 piece

CNC Wire erosion, 1 piece

Fast perforation, 1 piece

Automatic saw, 2 pieces

Tool sharpening, 1 piece

Transfer bench, 2 pieces

Spiral winding bench, 1 piece

Jigsaw, 1 piece

Our

Laser

Cutting

department

is

operating

as

a

different

company

under

the

name

of

HIZLAN

KESİM

UYGULAMALARI

LTD

has

been

operating

since

1996.

Hızlan

Kesim

Uygulamaları

which

has

been

providing

service

for

many

companies that made a brand in Turkish sector, as a pioneer on this field.

You may visit

for obtaining information related with Hızlan Lazer Kesim.

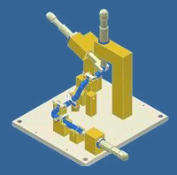

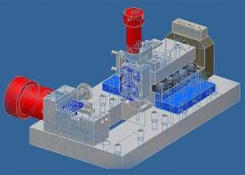

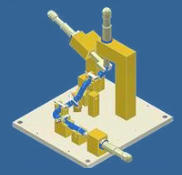

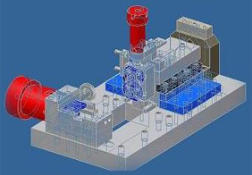

Design and Engineering

Project

Department

applications,

design,

drafting

or

CAD

data

sent

by

the

customer

are

formed

as

3D

in

Hızlanlar,

tools

that

are

required

for

manufacture

are

prepared

as

3D

in

computer

environment,

also,

in

order

to

be

able

to

catch

up

the

form

and

dimensional

nonconformance

that

could

arise

during

production

phase,

control

and

welding

fixtures

for

each

part

are

also

prepared

in

3D

computer

environment

and

their

manufactures

are

executed

in

processing center.

©2022 Hızlanlar Otomotiv. All rights reserved.

Caddesi No:58 (E-5 Karayolu

üzeri)

41400 Gebze/Kocaeli

Beylikbağı Mah. Güney Yanyol

0(262) 653 61 40 Pbx

0(262) 653 92 28

0(262) 653 61 41

Our quality certificates

Contact us

Our customers

Pipe Bending

Hızlanlar's

production

department

has

been

divided

into

three

separate

areas

as

CNC

Pipe

Bending,

Pipe

End

Forming

and

Assembly.

In

CNC

pipe

bending

department,

there

are

12

CNC

pipe

bending

machines

capable

of

bending

steel,

copper,

stainless,

brass

and

aluminum

pipes

starting

from

4.76

mm

diameter up to 80 mm diameter.

And

in

pipe

end

forming

department,

end

forming

round,

ring,

diameter

enlarging

and

reduction

operations

could

be

made

by

13

end

forming

machines,

and

also

starting

from

4.76

mm

diameter

up

to

80

mm

diameter.

In

our

assembly

department,

rubber

and

metal

combining

of

hydraulic

hoses and pipes are executed with 13 presses.

Production

is

controlled

in

its

every

phases

with

three

dimensional

measuring

device

and

3

dimensional

fixtures

approved

by

quality

control authorities.

Operators

working

in

production

are

developed

in

technological

and

also

in

social

areas

with

continuous

trainings

for

the

purpose

of

protecting

our

quality

level

worth

of

the

name

of

Hızlanlar

and

for

bringing it to better levels.

Machining

By

the

statistical

works

performed,

banjo

rings,

center

bolts,

hose

ends,

brake

heads,

nuts

and

bushings,

Cpks

of

lathes

are

continuously

kept

under

observation

and

produced

with

great care.

In our machining department;

Laser Cutting and Marking

Universal Milling, 1 piece

Universal Lathe, 5 pieces

CNC Lathe, 4 pieces

Automat With 6 Shafts, 1 pieces

Index ABC, 3 pieces

CNC process center, 1 piece

Surface grinding, 1 piece

Hydraulic presses, 6 pieces

Triple perforating, 1 piece

CNC Wire erosion, 1 piece

Fast perforation, 1 piece

Automatic saw, 2 pieces

Tool sharpening, 1 piece

Transfer bench, 2 pieces

Spiral winding bench, 1 piece

Jigsaw, 1 piece

Our

Laser

Cutting

department

is

operating

as

a

different

company

under

the

name

of

HIZLAN

KESİM

UYGULAMALARI LTD has been operating since 1996.

Hızlan

Kesim

Uygulamaları

which

has

been

providing

service

for

many

companies

that

made

a

brand

in

Turkish

sector, as a pioneer on this field.

You may visit

for obtaining information related with Hızlan Lazer Kesim.

Design and Engineering

Project

Department

applications,

design,

drafting

or

CAD

data

sent

by

the

customer

are

formed

as

3D

in

Hızlanlar,

tools

that

are

required

for

manufacture

are

prepared

as

3D

in

computer

environment,

also,

in

order

to

be

able

to

catch

up

the

form

and

dimensional

nonconformance

that

could

arise

during

production

phase,

control

and

welding

fixtures

for

each

part

are

also

prepared

in

3D

computer

environment

and

their

manufactures

are

executed

in

processing center.

Beylikbağı Mah. Güney

Yanyol Caddesi No:58 (E-

5 Karayolu üzeri) 41400

Gebze/Kocaeli

0(262) 653 61 40 Pbx

0(262) 653 92 28

0(262) 653 61 41

Our Customers

Our Quality Certificates

Contact Us

©2022 Hızlanlar Otomotiv. All rights reserved.